Its been an interesting week on the build. If you remember last time I was making good head way on the foot box and was preparing to installing the steering rack. (

I'm adding some notes to pictures to help define just what I'm talking about)

Well, the steering rack went on fine until I went to install the tierods on to the steering control arms. It turns out the the steering control arms have a tappered hole to line up with the tappered hole on the tierod.

.JPG)

So I thought no problem I'll just unbolt the control arm

and swap sides... no brainer and in theory should have been done in ½ hour.

Well, wishful thinking…. the control arm would not slide out pass the Lower

ball joint attached to the lower A-arm. and I could not remove the arm out the other direction. Well, I've now learned a new skill, breaking apart a ball joint. I hit the net to do some research and found a lot of "helpful" suggestions. Tried (and failed) at more then one. Finally had a chance to talk with my neighbor about my problem and he commented... no problem have them a part in a few minutes. Which he then took two sludge hammer and started whacking at the spindles and sure enough... pop the joint came apart! Well, not to be out done I grabbed the hammers and proceeded to done the same to the other joint and wham! success...

.JPG)

I felt pretty good about getting the steering corrected, installed and functional. It was time to move backwards (really, forwards with the build but towards the back of the car!) with installing the rear end into the chassis. I needed to enlist some muscle to lift and place the rear end into the proper location. I asked Jacob to come over and with Lori's and his help we were able to install the rear end! It weights around 200 pounds and had to be lifted and positioned about 10" off of the ground.

With all four corners ready for tires and rims it can be consider a "roller"!

Completed Front suspension

Completed rear suspension

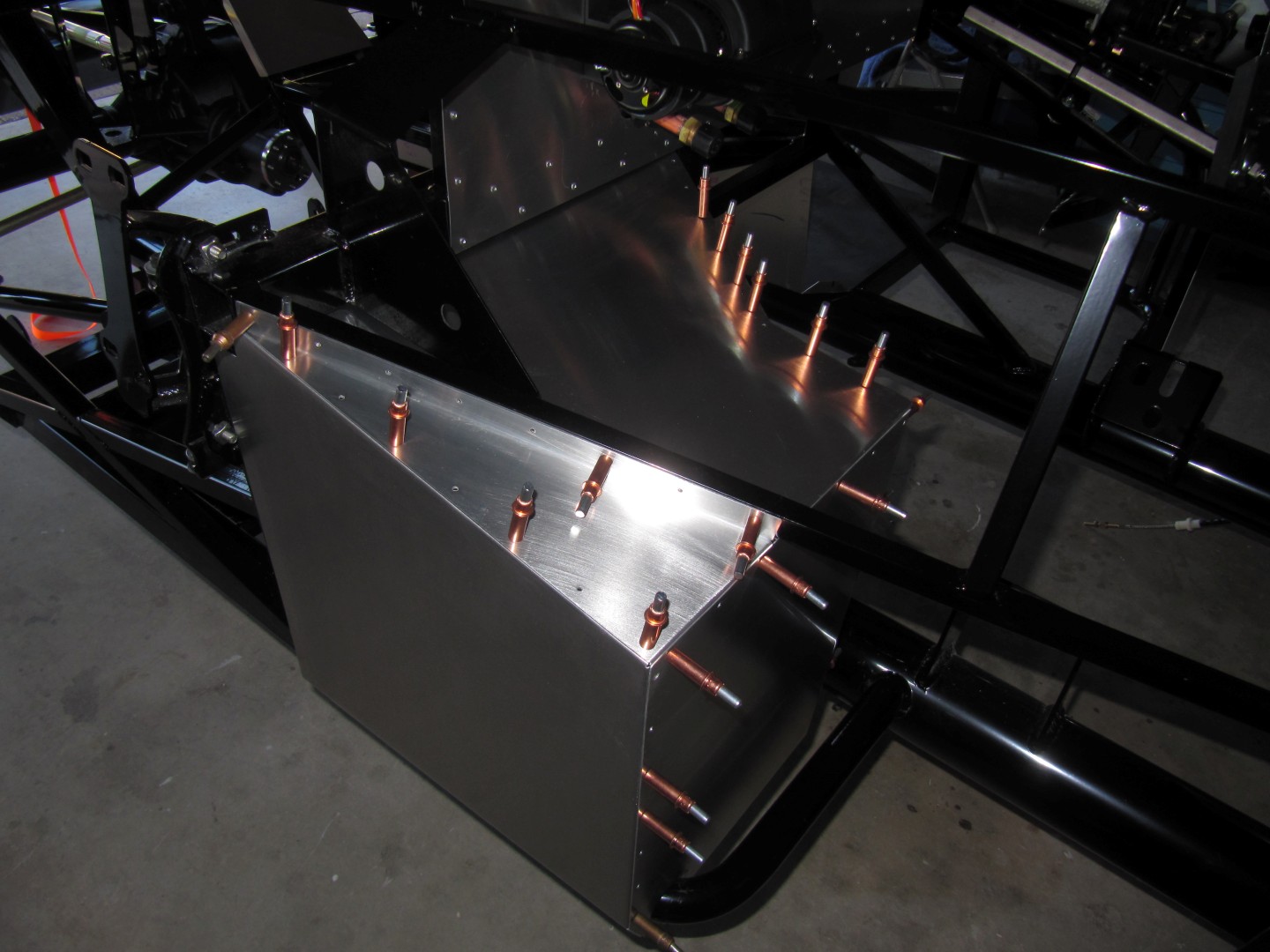

I feel like I'm making some great progress. This week I'm moving to get the Gas tank assembled and installed into the car.

and after that its on to install some of the sheet metal.

Still no decision on her name or her color...

.JPG)

.JPG)

.JPG)